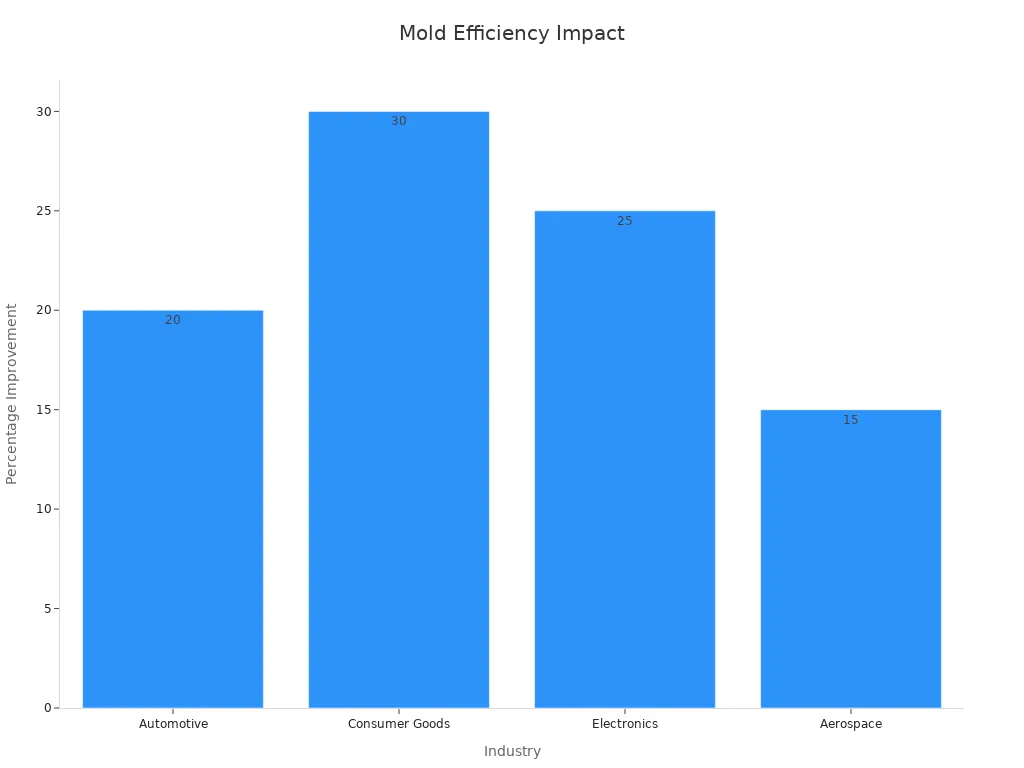

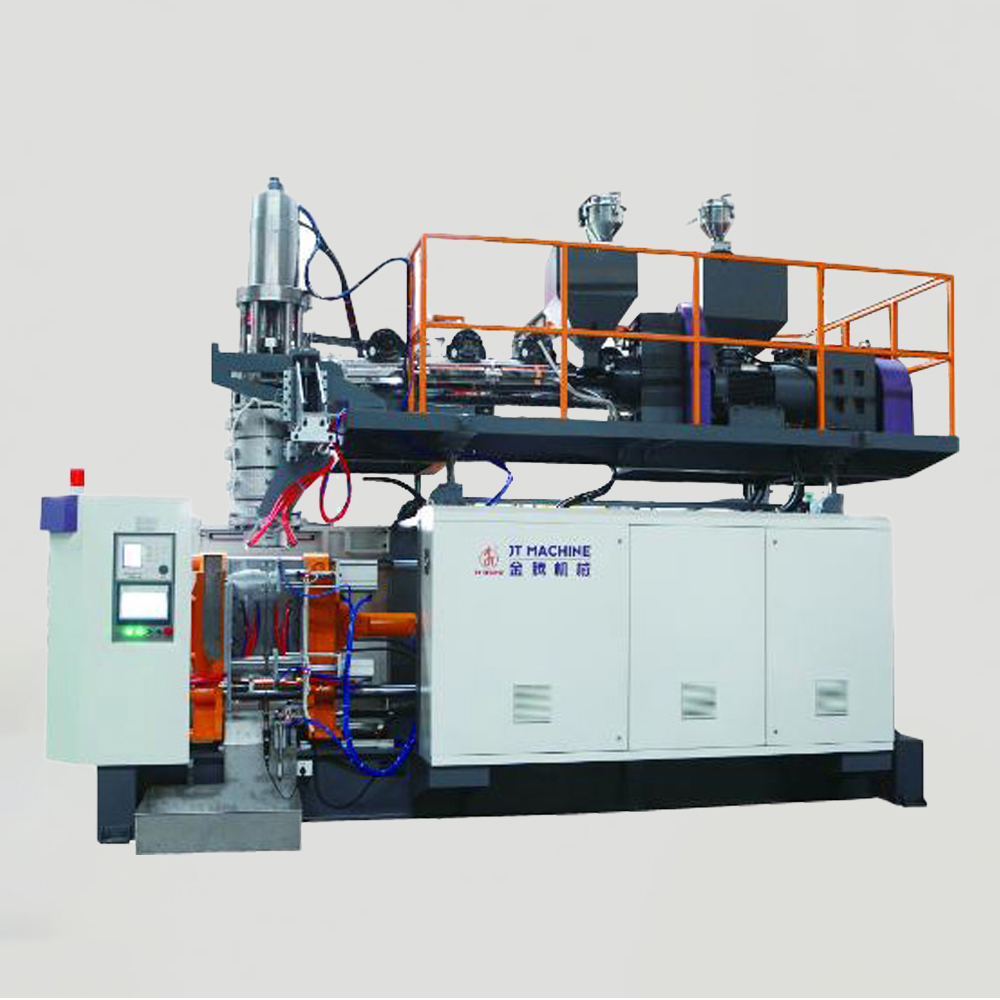

Efficiency drives success in bottle production. It ensures manufacturers meet growing market demands while controlling costs. For instance, increasing the Production Efficiency Ratio from 20 to 30 units per hour and reducing waste from 5% to 10% can significantly boost profitability. Advanced tools like the JT series bottle blowing machine help achieve these goals. Designed for versatility, it works seamlessly with materials like PE and PP, including applications in a PVC blowing machine factory, offering enhanced precision and speed. Whether you’re producing eco-friendly bottles or exploring injection stretch blow molding, optimizing processes becomes essential. Ready to transform your production line with a PP bottle blowing machine? Let’s dive in!

Choosing the Right Bottle Blowing Machine

Evaluating production needs and capacity

Selecting the right bottle blowing machine starts with understanding your production goals. Manufacturers need to assess factors like the number of bottles produced per hour, the size of the bottles, and the complexity of their designs. For instance, larger bottles require machines with higher clamping force, while intricate designs demand advanced mold compatibility.

Production capacity plays a critical role in this evaluation. Knowing the shot capacity of a machine helps manufacturers avoid costly mistakes. Undersized machines often lead to frequent mold changes, slowing down production. On the other hand, oversized machines can waste materials and increase operational costs. To find the right fit, manufacturers should calculate the mold cavity volume and shot weight based on the density of the plastic resin.

Other considerations include the type of material used, the space available for the machine, and energy efficiency. Machines that optimize space and energy usage not only save costs but also improve overall productivity.

Benefits of the JT series bottle blowing machine

The JT series bottle blowing machine stands out as a versatile and efficient solution for manufacturers. It accommodates a wide range of bottle sizes, from small 100 ml containers to large 50-liter products, making it ideal for diverse production needs. Its advanced control system ensures precision, maintaining the structural integrity of bottles across various designs.

This machine incorporates cutting-edge technologies like servo stretch blowing and infrared heating systems. These features minimize irregularities, ensure even heat distribution, and produce bottles with uniform wall thickness. Additionally, the JT series includes energy-saving mechanisms that reduce operational costs by up to 30%, making it a cost-effective choice for large-scale production.

Manufacturers benefit from its adaptability, as the JT series eliminates the need for multiple machines to handle different bottle types. Its innovative design and smart controls also reduce material waste, saving costs over long production runs.

Importance of energy-efficient and automated systems

Modern bottle blowing machines prioritize energy efficiency and automation, transforming production processes. Compared to traditional models, these machines cut electricity consumption by 20-30%, significantly lowering operational costs. The JT series, for example, uses servo motors and variable frequency drives to optimize energy usage.

Automation enhances production speed and reduces waste. Smart controls maintain tight tolerances, ensuring consistent bottle quality and minimizing defects. Lightweight designs and advanced materials further contribute to sustainability, making these machines an eco-friendly choice.

By investing in energy-efficient and automated systems, manufacturers can achieve faster production rates, lower costs, and improved bottle quality. These systems not only meet market demands but also align with the growing emphasis on sustainable manufacturing practices.

Optimizing Mold Design for Efficiency

Lightweight and durable mold materials

Using lightweight and durable materials for molds can significantly enhance production efficiency. Modern molds, often created through metal additive manufacturing, reduce thermal capacity and optimize steam distribution. This leads to shorter cycle times and lower energy consumption.

- Lightweight molds allow faster heating and cooling, which speeds up the production process.

- Experimental tests have shown that these molds outperform traditional designs, cutting cycle times and energy usage.

- Complex shapes can also be achieved with innovative mold designs, further improving manufacturing efficiency.

By adopting these advanced materials, manufacturers can save time and resources while maintaining high-quality output.

Customizing molds for diverse bottle designs

Custom molds tailored to specific bottle designs ensure flexibility and efficiency. Manufacturers can easily adjust molds to accommodate various sizes and shapes, streamlining operations and reducing downtime.

| Evidence Point | Description |

|---|---|

| Flexible Design Options | Adjustments for different bottle shapes enhance production efficiency. |

| Streamlined Operations | Tailored molds minimize downtime, boosting productivity. |

| Integration of Technologies | Automated systems reduce manual labor and waste, improving overall output. |

| Quality Control | Real-time monitoring ensures consistent, high-quality production. |

Custom molds also allow for the integration of advanced technologies, such as automated quality control systems, which further enhance efficiency and reduce waste.

Advanced mold technologies to reduce cycle times

Advanced mold technologies are game-changers for bottle production. Real-time monitoring systems provide immediate feedback, enabling quick adjustments when cycle times deviate. Alerts for even a 10% increase in cycle time ensure that efficiency remains on track.

These technologies also save time on manual tasks. For example, operators save up to 5 minutes per shift by eliminating paper reports, while management gains 20 minutes daily by avoiding manual data entry. Analytics further identify the best operators for specific molds, optimizing overall performance.

By leveraging these innovations, manufacturers can achieve faster production cycles and higher efficiency.

Managing Temperature Control in Bottle Blowing Machines

Consistent heating for preforms

Maintaining consistent heating for preforms is essential for producing high-quality bottles. Uneven heating often leads to irregular shapes and inconsistent wall thickness, which can compromise the final product. To avoid these issues, manufacturers should ensure that heating elements are clean and properly positioned to prevent hot spots. Using tools like infrared thermometers helps monitor and maintain even heat distribution.

Modern machines, such as the CPSB-LSS8, take this a step further. They use multi-point temperature detectors to ensure uniform heating across all preforms. These systems employ neural network-like modeling to automatically adjust heating power, keeping temperatures consistent. Additionally, real-time pressure detection ensures uniform blowing quality, resulting in stable and reliable bottles.

Other advanced systems, like those from TECH-LONG, precisely control preform heating and blowing parameters. This guarantees that every bottle meets the required specifications, reducing defects and improving production consistency.

Advanced cooling systems for faster production

Efficient cooling systems play a critical role in speeding up bottle production. By rapidly cooling the heated preforms, these systems shorten cycle times and enhance productivity. Performance studies highlight the impact of advanced cooling technologies:

| Metric | Result |

|---|---|

| Design-to-production cycle | Reduced to under 2 months |

| Printing speed | 30% faster (20h to 14h) |

| Heat treatment cycle | 70% shorter (4h vs 13h) |

| Heat dissipation improvement | 6% higher |

| Print distortion reduction | Less distortion observed |

These improvements demonstrate how advanced cooling systems not only accelerate production but also ensure better product quality.

Monitoring and adjusting temperature fluctuations

Monitoring and adjusting temperature fluctuations is key to maintaining process stability. Comprehensive temperature monitoring ensures product integrity and compliance with industry standards. Real-time data allows manufacturers to make informed decisions, such as adjusting settings to address temperature spikes.

| Evidence Description | Key Insights |

|---|---|

| Comprehensive monitoring of temperature-controlled materials | Ensures product integrity and compliance throughout the supply chain. |

| Real-time temperature monitoring data | Enables better decision-making and process adjustments. |

| Allowable excursion criteria | Reduces unnecessary waste by allowing flexible product evaluations. |

| Regulatory compliance | Ensures adherence to proper temperature conditions for safety and efficacy. |

By leveraging these insights, manufacturers can minimize defects, reduce waste, and maintain consistent production quality. Temperature control remains a cornerstone of efficient bottle production.

Ensuring Stable Air Pressure and Gas Quality

Role of consistent air pressure in bottle uniformity

Stable air pressure plays a critical role in ensuring bottle uniformity during production. When air pressure fluctuates, bottles can develop uneven walls or weak spots, leading to defects. Consistent pressure ensures that every bottle inflates evenly, maintaining its shape and structural integrity. Manufacturers can achieve this by using advanced air pressure regulators that monitor and adjust pressure levels in real time.

Think of it this way: air pressure acts like a sculptor shaping the bottle. If the sculptor’s hand wavers, the final product won’t look right. Similarly, steady air pressure guarantees that each bottle meets quality standards, reducing waste and improving efficiency.

High-quality compressed air systems for reliability

High-quality compressed air systems are essential for reliable bottle production. These systems provide clean, consistent, and pure air, which is especially important in industries like food and beverage. Contaminated air can compromise product safety, so maintaining air purity is non-negotiable.

- Compressed air ensures hygiene during processes like filling and sealing.

- It’s often called the “fourth utility” because of its versatility and reliability.

- These systems work seamlessly with various tools and machinery, making them indispensable for bottle production.

By investing in high-quality compressed air systems, manufacturers can enhance both productivity and product safety.

Regular inspection of air supply systems

Routine inspections of air supply systems prevent unexpected breakdowns and maintain efficiency. Over time, components like filters and valves can wear out, leading to pressure drops or contamination. Regular checks help identify and fix these issues before they escalate.

A simple maintenance schedule can make a big difference. For example, inspecting filters monthly and replacing them as needed keeps the system running smoothly. By staying proactive, manufacturers can avoid costly downtime and ensure consistent air quality throughout the production process.

Tip: Keep a log of inspections and maintenance tasks. This helps track performance and ensures no detail gets overlooked.

Enhancing Operator Skills for Better Efficiency

Training operators on advanced systems like the JT series

Operators play a vital role in maximizing the potential of advanced machinery, such as the JT series bottle blowing machine. Proper training ensures they understand the machine’s features, like its intuitive Siemens IE V3 1000 touch screen and energy-efficient hydraulic system. Hands-on training sessions allow operators to familiarize themselves with these systems, reducing errors and improving production speed.

A study on training programs revealed significant benefits. For example:

| Evidence Description | Impact on Performance | Financial Return |

|---|---|---|

| Training led to a 11-68% reduction in BOD/TSS levels | Significant improvement in plant performance metrics | $91 return for every dollar invested in training |

| Training improved skills and increased plant effectiveness | Overall improvement ranged from 112% to 334% over pre-training levels | High investment in plant per operator, over $64,000 |

| Case studies indicated strong beneficial influence of training | Improved performance in historically substandard plants | N/A |

These results highlight the value of investing in operator training to unlock the full potential of modern machinery.

Encouraging continuous learning and skill development

Encouraging operators to embrace continuous learning fosters a culture of innovation and adaptability. Regular workshops and refresher courses keep them updated on the latest industry trends and technologies. For instance, learning about advanced mold designs or temperature control systems can help operators identify opportunities to improve efficiency.

Managers can also implement mentorship programs where experienced operators guide newer team members. This approach not only builds confidence but also ensures knowledge transfer across the workforce. By prioritizing skill development, manufacturers can create a team that consistently delivers high-quality results.

Empowering operators to troubleshoot and optimize processes

Empowering operators to troubleshoot and optimize production processes reduces downtime and enhances efficiency. When operators can identify and resolve issues independently, production lines run more smoothly. Effective maintenance scheduling and real-time monitoring tools, such as centralized dashboards, enable operators to address problems before they escalate.

- Predictive maintenance forecasts equipment failures, allowing proactive planning.

- Regular equipment audits help detect wear and tear early, preventing unexpected breakdowns.

- Shared dashboards provide a clear view of operational metrics, facilitating quick decision-making.

By equipping operators with the right tools and knowledge, manufacturers can minimize disruptions and maintain consistent output.

Regular Maintenance and Care of Bottle Blowing Machines

Preventive maintenance schedules for longevity

Preventive maintenance is the backbone of keeping a bottle blowing machine running smoothly. By scheduling regular checkups, manufacturers can catch potential issues before they escalate into costly breakdowns. Think of it like taking your car for an oil change—it’s a small effort that saves you from bigger problems down the road.

Research shows that implementing preventive maintenance significantly improves machine reliability and reduces downtime. For example:

| Machine | Reliability Before | Reliability After | Improvement (%) | Average Time Between Failures Before | Average Time Between Failures After | Increase (%) |

|---|---|---|---|---|---|---|

| Alba 26 | 0.45963 | 0.55756 | 21% | 6.87898 | 9.77866 | 42% |

| Crupp 21 | 0.4856 | 0.5430 | 12% | N/A | N/A | 46% |

These numbers highlight how a simple maintenance schedule can make a big difference. Minor production stops, which can occur up to 20,000 times a year, may seem insignificant at first. However, they add up quickly, impacting both productivity and profitability. A systematic approach, like Reliability-Centered Maintenance (RCM), anticipates wear and tear, ensuring machines stay in top condition.

Tip: Create a maintenance calendar and stick to it. Regular inspections and tune-ups will keep your production line humming along without interruptions.

Automatic lubrication systems in the JT series

The JT series bottle blowing machine takes maintenance to the next level with its automatic lubrication system. This feature ensures that all moving parts receive the right amount of lubrication at the right time, reducing wear and tear. Operators no longer need to manually grease components, which saves time and minimizes human error.

Automatic lubrication also extends the lifespan of critical parts, such as the hydraulic system and linear guides. By keeping these components in optimal condition, the machine operates more efficiently and with less downtime. This system is particularly beneficial for high-volume production lines, where even a short delay can disrupt schedules.

Note: The JT series’ lubrication system not only improves performance but also reduces maintenance workload, freeing up operators to focus on other tasks.

Inspecting and replacing worn-out components

Even with the best maintenance practices, some parts will eventually wear out. Regular inspections help identify these components before they fail. For example, filters, valves, and screws are common wear points in bottle blowing machines. Replacing them promptly ensures the machine continues to perform at its best.

A proactive approach to inspections can prevent unexpected breakdowns. Operators should check for signs of wear, such as unusual noises, slower cycle times, or inconsistent bottle quality. Keeping a log of these inspections helps track the condition of each component, making it easier to plan replacements.

Callout: Don’t wait for a part to fail completely. Replacing worn components early saves money and avoids costly downtime.

By combining preventive maintenance, automatic lubrication, and regular inspections, manufacturers can maximize the efficiency and lifespan of their bottle blowing machines. These practices not only reduce costs but also ensure consistent, high-quality production.

Adjusting Production Speed and Process Parameters

Balancing speed and quality to minimize defects

Finding the right balance between production speed and quality is essential for reducing defects. Rushing the process often leads to errors, while overly cautious speeds can slow down output. Manufacturers can achieve this balance by integrating advanced monitoring systems that detect issues early. For example, sensors can identify irregularities in bottle thickness or shape, allowing operators to make quick adjustments.

A study of various industries highlights the benefits of balancing speed and quality:

| Case Study | Findings |

|---|---|

| Electronics Assembly Plant | Sensor data improved efficiency and reduced error rates. |

| Automotive Parts Manufacturer | Worker training programs lowered defect rates, proving the value of education. |

| Molding Process Analysis | Better temperature control reduced defects, ensuring consistent quality. |

These examples show how combining technology and training can enhance both speed and quality, minimizing waste and boosting efficiency.

Fine-tuning settings for optimal performance

Small adjustments to machine settings can make a big difference in production efficiency. Operators should regularly review parameters like air pressure, temperature, and cycle times to ensure they align with production goals. Machines like the JT series make this process easier with intuitive controls and real-time feedback.

For instance, adjusting the clamping force for larger bottles or tweaking the heating profile for different materials can prevent defects. Regularly testing these settings ensures the machine operates at peak performance, delivering consistent results.

Tip: Keep a log of successful settings for different bottle designs. This helps operators replicate optimal conditions quickly.

Leveraging data analytics for real-time adjustments

Data analytics transforms how manufacturers optimize production. Real-time insights allow operators to spot inefficiencies and make immediate changes. For example:

- Adjust workflows to address bottlenecks.

- Improve product quality by identifying defects early.

- Enhance supply chain management through better planning.

A step-by-step approach to using analytics can further streamline operations:

| Step | Description |

|---|---|

| 1 | Identify machines that frequently disrupt production. |

| 2 | Analyze failure patterns, such as overheating motors. |

| 3 | Develop predictive models using sensor data like temperature and vibration. |

| 4 | Schedule maintenance to minimize downtime. |

By leveraging these tools, manufacturers can reduce machine downtime, improve efficiency, and maintain high-quality standards. Data-driven decisions ensure production lines stay agile and responsive to challenges.

Implementing Quality Control Systems

Regular inspections during production

Regular inspections keep production lines running smoothly. By checking bottles during production, manufacturers can catch defects early. This prevents waste and ensures consistent quality. Operators should monitor key factors like wall thickness, shape, and material distribution. Simple tools, such as calipers or gauges, can help with these checks.

Real-time monitoring systems take this a step further. Advanced sensors track production parameters continuously, providing instant feedback. For example, if a bottle’s thickness falls outside the acceptable range, the system alerts operators immediately. This allows quick adjustments, reducing downtime and improving efficiency.

Tip: Schedule inspections at regular intervals to avoid missing potential issues.

Automated quality control tools for precision

Automation has revolutionized quality control. Tools like computer vision and AI-powered systems identify defects with incredible accuracy. These technologies outperform human inspection by detecting even the smallest irregularities.

For instance, automated inspection systems can scan hundreds of bottles per minute. They spot flaws like uneven surfaces or weak spots that might go unnoticed otherwise. This ensures every bottle meets high standards before leaving the production line.

| Quality Control Application | Description |

|---|---|

| Real-time monitoring | Advanced sensors and IoT devices track production parameters continuously |

| Automated inspection systems | Computer vision and AI-powered technologies identify defects with greater accuracy than human inspection |

| Lean manufacturing | Focuses on eliminating waste and improving efficiency while maintaining quality |

| Six Sigma methodology | Reduces process variation to achieve near-perfect quality levels |

By adopting these tools, manufacturers can boost precision and reduce waste.

Addressing defects promptly to reduce waste

Quick action is key when defects occur. Ignoring small issues can lead to bigger problems, increasing waste and slowing production. Operators should address defects as soon as they’re detected.

For example, if a batch of bottles shows uneven thickness, operators can adjust the machine settings immediately. This prevents further defects and saves materials. Using Six Sigma methodology helps reduce process variation, ensuring consistent quality.

Callout: A proactive approach to defects saves time, money, and resources.

By combining regular inspections, automated tools, and prompt action, manufacturers can maintain high production standards while minimizing waste.

Boosting bottle production efficiency requires a combination of smart strategies and the right tools. Advanced technology, like the JT series bottle blowing machine, streamlines processes and reduces waste. Skilled operators, trained to handle modern systems, can quickly troubleshoot and optimize performance. Regular maintenance ensures machines run smoothly, preventing costly downtime.

- Advanced machines improve automation and control.

- Trained operators enhance efficiency by responding to issues effectively.

- Maintenance reduces breakdowns and increases uptime.

By adopting these practices, manufacturers can achieve faster, more reliable production. Start implementing these tips today to stay ahead in the competitive market!

FAQ

What makes the JT series bottle blowing machine energy-efficient?

The JT series uses servo motors and variable frequency drives, reducing energy consumption by 15-30%. This design ensures cost savings and supports sustainable manufacturing practices.

How often should manufacturers perform maintenance on bottle blowing machines?

Preventive maintenance should occur monthly. Regular inspections of filters, valves, and lubrication systems help avoid breakdowns and ensure consistent performance.

Can the JT series handle different bottle sizes and designs?

Yes! The JT series adapts to various bottle sizes, from 20 to 50 liters, and supports diverse designs with its flexible mold compatibility and advanced control system.

Tip: Always consult the machine manual for specific maintenance schedules and operational guidelines.

Post time: May-26-2025