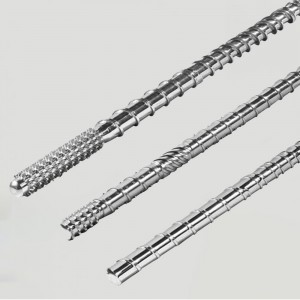

Single Screw Plastic Extruder

With the improvement of environmental awareness, plastic recycling has become a hot issue today. The single screw extruder plays an important role in the recycling process of plastics. By recycling plastic waste, after melting and extrusion, it can be made into plastic products again. This not only saves raw materials, but also reduces environmental pollution.

The working principle of the single screw extruder is as follows:

1. Feeding: plastic particles or powder are added to the feed section of the screw extruder through the feed port.

2. Feed and melt: The screw rotates in the barrel to push the plastic particles forward, and apply high temperature and high pressure at the same time. As the plastic is heated by friction inside the screw and barrel, the plastic begins to melt and form a uniform melt.

3. Pressure increase and melting zone: the screw thread gradually becomes shallow, making the traffic path narrow, thereby increasing the pressure of the plastic in the barrel, and further heating, melting and mixing the plastic.

4. Extrusion: In the barrel behind the melting zone, the screw begins to change shape, pushing the molten plastic toward the barrel outlet, and further pressurizing the plastic through the mold hole of the barrel.

5. Cooling and shaping: The extruded plastic enters the cooling water through the mold hole for rapid cooling, so that it is hardened and shaped. Typically, the die holes and cooling system of the extruder are designed according to the desired product shape.

6. Cutting and collection: The extruded molding is continuously extruded from the mold hole, and then cut to the required length, and collected and packaged by conveyor belts or other collection devices.

1. Application of automation technology

With the continuous development of automation technology, single-screw extruders are also constantly updated. The automatic control system can realize the real-time monitoring and adjustment of the running state of the extruder, improve the production efficiency and quality stability. The integrated design and intelligent operation interface also make the operation easier to understand.

2. The demand for green environmental protection

In the world, the need for green environmental protection is becoming more and more urgent. Single-screw extruders will also develop in a more environmentally friendly direction. For example, the development of more environmentally friendly rubber raw materials and biodegradable materials, and the research of new energy saving and consumption reduction technologies are the direction of future development.